The NXTGEN HIGHTECH growth fund program focuses on advancing integrated photonics in order to support the future digitalization of society. To scale integrated photonics in commercial applications, there is a need for developing equipment capable of mass-producing photonic components. The project aims to create production equipment for integrated photonic devices, with a focus on standardizing both front-end and back-end manufacturing processes for Photonic Integrated Circuits (PICs).

Key aspects include:

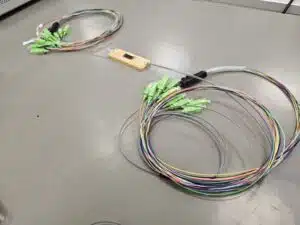

Back-end process: Assembly, testing, and packaging of components, including interfaces like connectors and fibers.

Front-end process: Development of new photonic properties and technologies such as PZT, CVD, and NanoImprint for wafer production.

Production of multiple product families: Targeting common substrates (SiN, InP) and optical coupling options like vertical, horizontal, and flexible designs.

Supply chains: Creating specific chains for each product family to test and compare new machines and processes against industry standards.

The program is developing 10 new machines, aimed at foundries in the Netherlands and globally, with applications across sectors like healthcare, agrifood, logistics, and datacom.

MicroAlign is part of the NXTGEN subproject Semicon 09. In Semicon09, efforts are focused on developing production equipment for integrated photonics to enable mass production of these components and devices. The project concentrates on standardizing both front-end and back-end production processes for manufacturing wafers with Photonic Integrated Circuits. The goal is to develop machines for various product families that standard utilize substrates such as SiN and InP. These developments are crucial for assembling the components, interfering various coupling methods such as vertical and horizontal.

Learn more: https://nxtgenhightech.nl/en/semiconductors/projects/#semicon08