Towards ultra-low loss fiber array alignment

Fiber array alignment is the process of positioning multiple optical fibers in a precise and accurate way to couple light with photonic integrated chips (PICs) or other optical devices. In this way, light can be employed by PICs to perform data transmission, sensing, or computation tasks. Fiber array alignment is one of the critical steps for ensuring high performance and efficiency of photonic devices, requiring fiber positioning accuracy in the nm range.

MicroAlign: Ultra-high accuracy fiber array

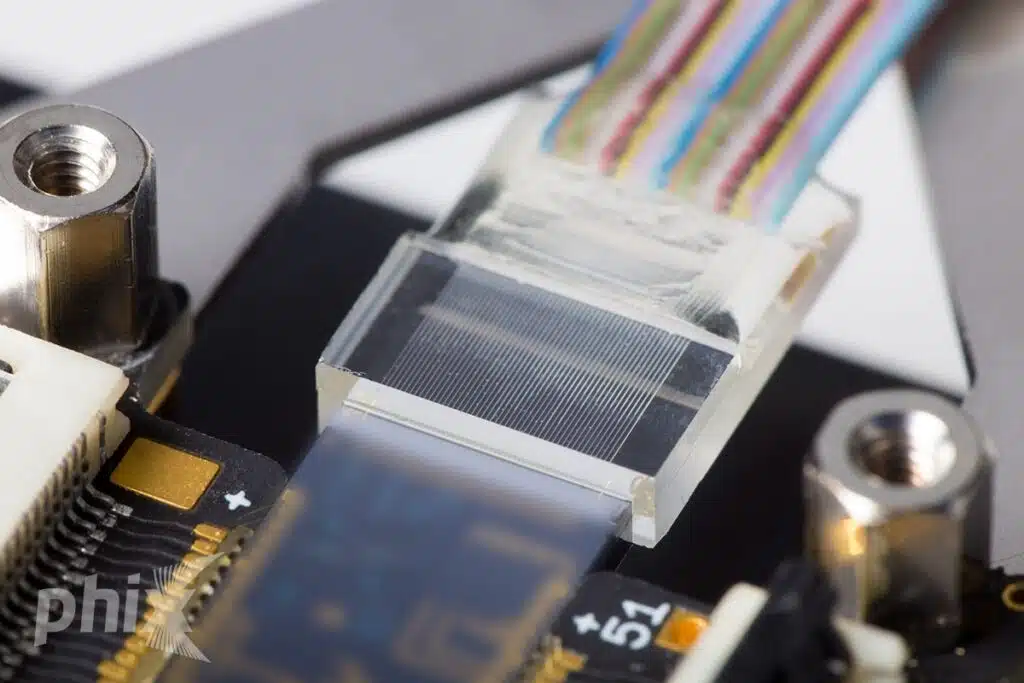

MicroAlign technology brings individual fiber position control into a fiber array. Merging this revolutionary tuning capability with core-based active alignment allows an accuracy improvement of 10x compared to current passive alignment solutions, without trading alignment speed. Indeed, with MicroAlign technology all the fibers can be controlled individually and at the same time, making any alignment task highly parallelizable.

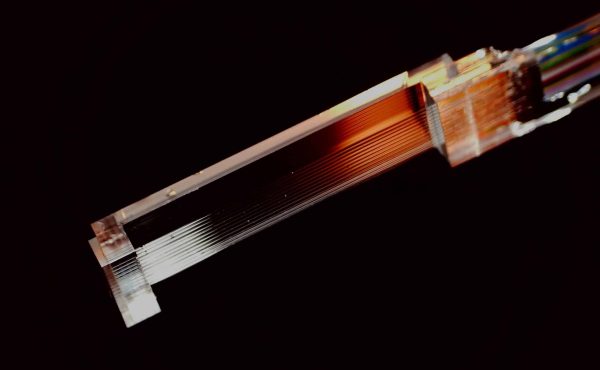

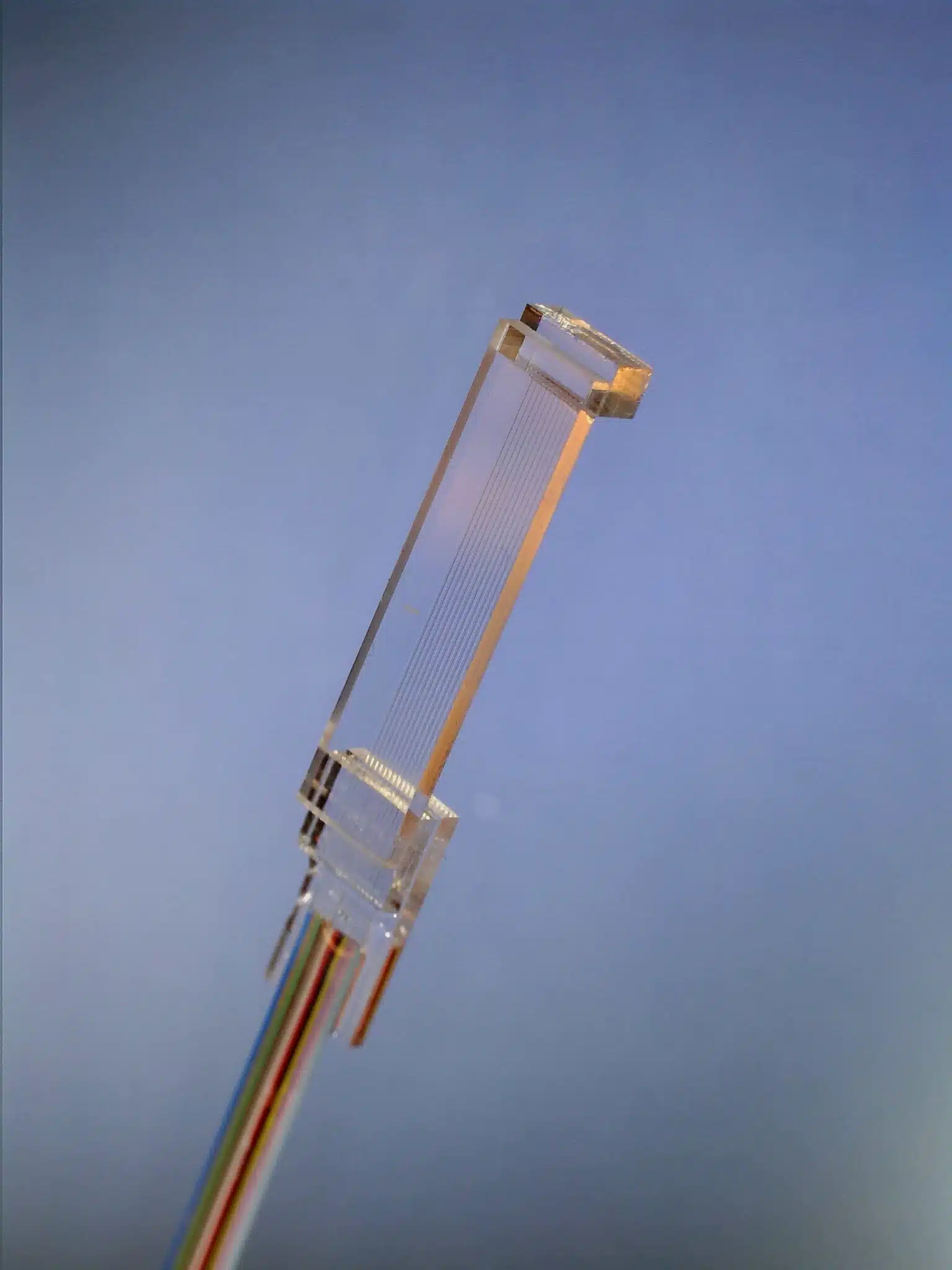

MicroAlign alignment system in a edge-coupled PIC testing application.

How does it work?

It's a three-step process

Step 1 I Fiber array loading

A commercially available fiber array featuring protruding fibers is loaded on the alignment tool using a fine-tuning adjustment screw embedded in the MicroAlign mechanical stage (provided together with the tool).

Step 2 I First light search and course alignment

The fiber array loaded on the MicroAlign tool is brought in proximity of the device under test (i.e. a multi-port PIC or another fiber array) and the first light search is initiated. As the first light is captured by any of the fibers, the course alignment can begin. The objective of this operation is to correct the initial axial and angle misalignments and position the cores of the fiber array a few micrometers away from the target position. To operate correctly, the MicroAlign tool requires each fiber core to be pre-aligned with an accuracy of about ± 5μm distance from the optimal target.

Step 3 I Fine-alignment

After (Step 2) is completed the fine alignment can begin. The position of each fiber within the fiber array is manipulated, and the corresponding coupled optical power is maximized using an active feedback loop. The fine alignment procedure typically requires less than 20 seconds and achieves a residual core misalignment of ~100 nm for all the fibers.

MicroAlign solution in a nutshell

Main features

- Friction-free individual fiber position control

- Per fiber 2-Dimensional position tuning range ±20 μm

- Position control resolution ~20 nm

- Fast response time (< 20 ms)

Alignment system capabilities

- Supports up to 12 fibers at 500, 254 and 250 μm pitch

- Compatible with O-Band and C-Band wavelength operation

- Per fiber core-based active alignment

- Typical fine alignment time < 20 s

Key advantages

Parallel alignment

Per-fiber minimal coupling loss

Wide fine alignment range

Scalable and versatile

Standard approach

Commercially available solutions for multi-port chip-to-fiber connection rely on the use of standard fiber arrays, which are aligned to the PIC (or other optical devices) typically using active alignment of the outer fibers. While the outer fibers can achieve optimal coupling performance, the coupling efficiency for all the remaining fibers is directly related to the fabrication tolerances of the fiber array. Indeed, in a standard fiber array, the fibers are placed in physical contact with a glass holder equipped with engraved v-grooves (passively alignment). Once the v-grooves are populated with optical fibers, adhesive, and a lid are applied to permanently fix the assembly. Due to the nature of the assembly procedure, no positioning control can be dedicated to the core position of each optical fiber, exposing the final component quality to be negatively affected by imperfections related to adhesive shrinkage, fiber core eccentricity, and cladding diameter accuracy. These imperfections lead to residual fiber core misalignments of about ± 0.5 µm, which in turn negatively affect the coupling efficiency during the fiber array alignment process. In other words, the standard fiber array alignment approach cannot guarantee optimal coupling efficiency for each fiber.

MicroAlign technology: I want to know more

Fill in the form and download a free PDF about MicroAlign Technology

You will get a confirmation in your mail to be able to download the document. Note: also check your spam. When you have filled in your data you will be registered for future newsletters. But you can unsubscribe at any time or directly in the first mail you get (with the link to the document).