Careers

Internship - Master Graduation Project

Introduction

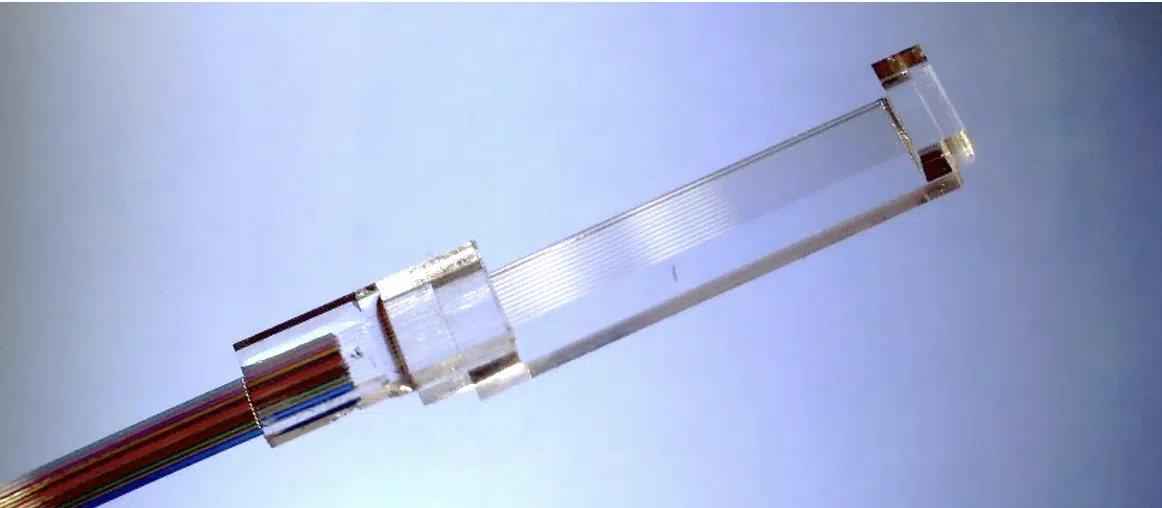

Optimal coupling efficiency between optical fiber arrays and photonic chips is limited by the core positioning imperfections in fiber arrays assembled in V-groove technology and based on passive alignment. MicroAlign produces fiber arrays where the fiber cores are independently and actively aligned to achieve the highest pitch accuracy (Figure 1). This enables the most efficient coupling between fiber arrays and chips [1]. To achieve this, the optical fibers are simultaneously and independently aligned by means of MicroAlign MEMS (Micro Electro-Mechanical Systems) technology, which enables nanoscale actuation resolution per fiber over a range of several micrometers [2]. However, epoxy non-idealities, like for example shrinkage, affect the position of the fibers during curing. Numerical models can be a powerful tool to gain more insight into this time dependent epoxy behavior and its influence on fiber position. Therefore, in this project you will work on the development of a numerical model, based on experimental observations, to simulate the capillary filling, using epoxies with different rheological properties.

Master’s Graduation Project Description

In this project, your work will be focused on the development of a numerical tool to accurately reproduce the effects of the adhesive behavior before and after curing phases of the fiber array manufacturing. Moreover, you will need to perform several experiments with different adhesives to extract the main relevant parameters of the materials used in the process and feed them into the simulation tool. Finally, you will validate the simulation results with experimental data.

This project is performed in cooperation with the Mechanical Engineering department of Eindhoven University of Technology.

Student profile

- Programming skills: good knowledge of Python, or MATLAB

- Knowledge of Computational Fluid Dynamics (CFD), the Finite Element method (FEM) and mathematical modeling

- Knowledge of non-Newtonian rheology

- Familiarity with adhesive properties, and interaction with microchannel surfaces

- Good analytical and problem-solving skills

- Hands on, in experimentally testing and validation

References:

[2] Cardarelli, Simone, et al. “Active alignment of densely spaced optical fibers for high-accuracy fiber arrays manufacturing.” Proc. of SPIE Vol. Vol. 13372.

Send your resume along with your message to vacancy@microalign.nl

Our team will review your resume and contact you with the results.