High-accuracy fiber arrays with core-active alignment

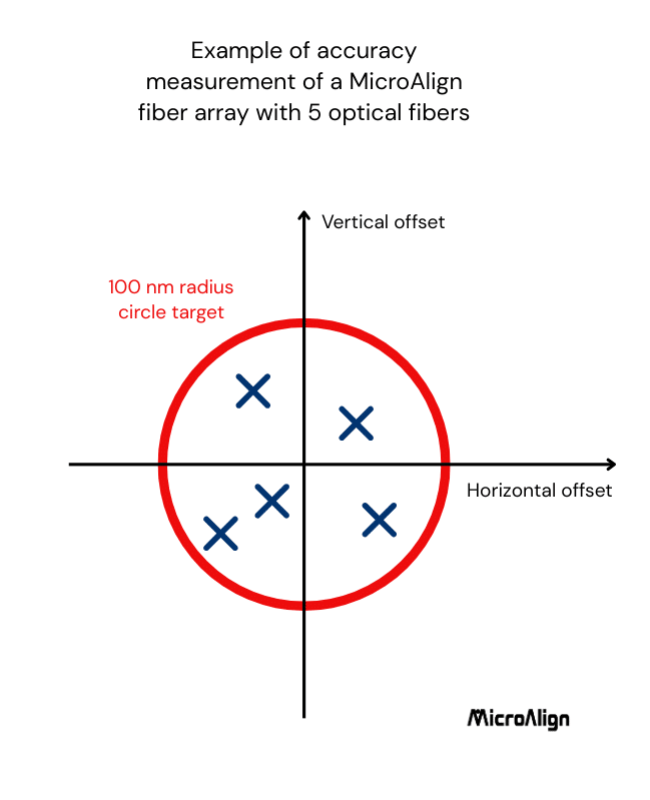

MicroAlign has developed technology to manufacture optical fiber arrays with the highest-accuracy core positioning. The cores of the optical fibers are actively aligned to a high-accuracy reference to enable a final core-positioning accuracy of < 100 nm (RMS) across the fiber arrays.

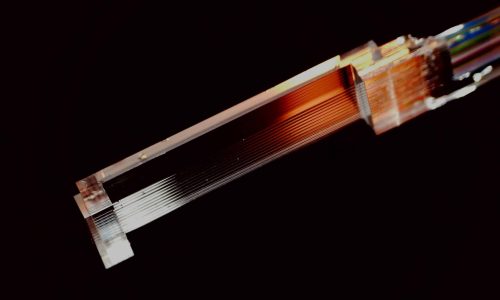

Nano positioning MEMS technology

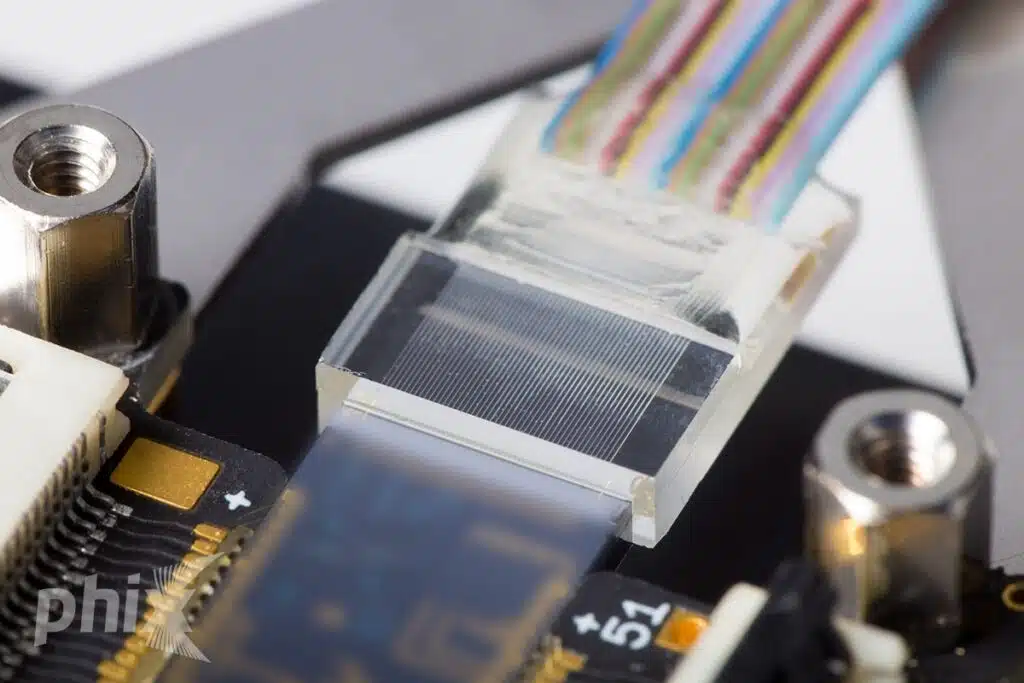

The optical fibers are simultaneously and independently aligned by means of our proprietary MEMS (Micro Electro-Mechanical Systems) technology, which enables nanoscale actuation resolution per fiber over a range of several micrometers.

How does it work?

- Optica fibers are loaded into our MEMS tool capable of deflecting the tip of each fiber vertically and horizontally.

- The fibers are then inserted into the through-holes of a UV-light-transparent ferrule for final alignment.

- Optical beams are launched into the fibers so that active alignment of the fiber cores can be achieved with respect to a high-accuracy reference device. When the alignment routine is complete, UV light is shined on the fiber-ferrule assembly for permanent fixation.

The problem

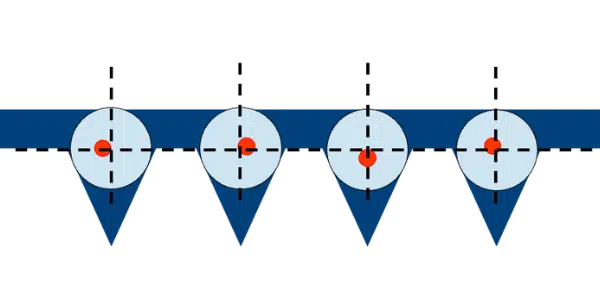

Optimal coupling efficiency between optical fiber arrays and photonic chips is limited by the core positioning imperfections in fiber arrays assembled in V-groove chip technology and based on passive alignment.

V-groove (passive alignment)

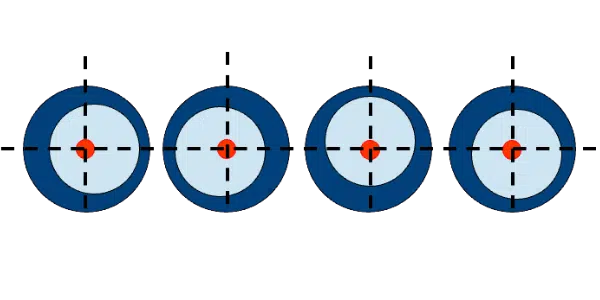

The solution

MicroAlign produces fiber arrays where the fiber cores are independently and actively aligned to achieve the highest pitch accuracy. This enables the most efficient coupling between fiber arrays and chips.

MicroAlign (active alignment)

How do we qualify our fibre arrays?

Measuring the core position of high-accuracy fiber arrays is not an easy task!

There is currently no equipment available that can measure core positioning in a fiber array with an accuracy better than 100 nanometers.

MicroAlign has developed proprietary technology that enables precise measurement of the position of actively aligned fiber cores — with unprecedented accuracy, repeatability, and speed.

Our measurement equipment measures the vertical and horizontal offset of each fiber core relative to its ideal position.

What do we mean by core ideal position in a nutshell:

- Imagine you can create a virtual 1D linear grid of points with the same pitch as targeted by a produced fiber array.

- Overlap the 1D linear grid to the measured set of core positions by minimizing the distances between each fiber core position and the related virtual points.

- Draw the obtained vertical and horizontal distance of each fiber core from the virtual point on a 2D graph … are the crosses very close to the 100 nm target offset circle? Then it is a MicroAlign fiber array!

Standard approach

Commercially available solutions for multi-port chip-to-fiber connection rely on the use of standard fiber arrays, which are aligned to the PIC (or other optical devices) typically using active alignment of the outer fibers. While the outer fibers can achieve optimal coupling performance, the coupling efficiency for all the remaining fibers is directly related to the fabrication tolerances of the fiber array. Indeed, in a standard fiber array, the fibers are placed in physical contact with a glass holder equipped with engraved v-grooves (passively alignment). Once the v-grooves are populated with optical fibers, adhesive, and a lid are applied to permanently fix the assembly. Due to the nature of the assembly procedure, no positioning control can be dedicated to the core position of each optical fiber, exposing the final component quality to be negatively affected by imperfections related to adhesive shrinkage, fiber core eccentricity, and cladding diameter accuracy. These imperfections lead to residual fiber core misalignments of about ± 0.5 µm, which in turn negatively affect the coupling efficiency during the fiber array alignment process. In other words, the standard fiber array alignment approach cannot guarantee optimal coupling efficiency for each fiber.

MicroAlign technology: I want to know more

Fill in the form and download a free PDF about MicroAlign Technology

You will get a confirmation in your mail to be able to download the document. Note: also check your spam. When you have filled in your data you will be registered for future newsletters. But you can unsubscribe at any time or directly in the first mail you get (with the link to the document).