R&D Projects

MicroAlign in European & International Collaborations

At MicroAlign, we are actively involved in several European and international innovation projects that push the boundaries of photonics and advanced manufacturing.

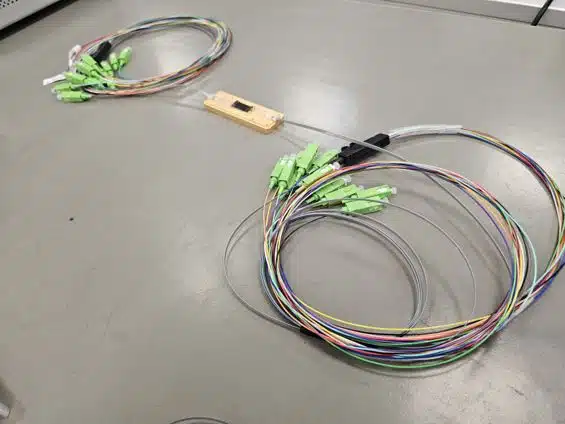

Our team contributes high-precision fiber array technology to collaborative R&D initiatives that aim to accelerate breakthroughs in:

Quantum photonics, Integrated photonics packaging, Next-generation communication systems, Automated fiber alignment.

These projects connect us with a diverse network of research institutions, leading industry partners, and forward-thinking startups across Europe and beyond. We are currently participating in multiple EU-funded and trilateral innovation programs, including efforts under the Horizon Europe framework, PhotonDelta ecosystem, and cross-border collaborations in Germany, France, and the Netherlands.

Through these partnerships, MicroAlign not only advances its proprietary High Accuracy Fiber Arrays (HAFA) but also helps shape the future of scalable, high-performance photonics solutions.

TUF-ToPiQC

Toward Utility and Fault-Tolerance for Photonic Quantum Computing. The consortium combines world-leading expertise from France, Germany, and the Netherlands, both at the academic and industrial levels, to provide an unprecedented push to move photonic quantum computing towards utility and fault tolerance.

ADOPTION

ADOPTION works toward proving a low power and low-cost solution for intra-data centre networks employing copackaging of the optical (CPO) transceivers with the packet switch chip.

FIT4Q

Fiber array Innovation Technology for Quantum photonics. A project funded through the European Trilateral Collaboration on Quantum Innovation. The project aims to realize a scalable quantum computing architecture capable of assisting a high number of quantum nodes with optimal optical quantum computing efficiency

NXTGEN

As part of Semicon 09 within the Dutch NXTGEN Hightech program, we are working on optimizing the alignment of optical fibers in fiber arrays, achieving sub-micron precision through an innovative micro-electromechanical system (MEMS).